For the uninitiated, the prospect of drilling into concrete may seem next to impossible, like something that should be avoided at all costs or definitely handed off to a professional. But the fact is, if you have the right tools and a little bit of know-how, even the greenest do-it-yourselfer can get the job done. If you’re doing something along the lines of mounting shelving on a garage or basement wall, you’ll find that drilling into concrete isn’t so different from drilling into anything else. And we’re here to make sure you’re ready to go when it’s time to take drill bit to concrete. So let’s dig in and make sure you have everything you need, from the basic techniques to the perfect concrete drill.

First off, we’ll detail the kind of concrete drilling any weekend warrior can handle. Then we’ll take a look at heavy-duty core drilling that you might want to hire out to a professional contractor with a diamond core rig and the right concrete drill bit for the work. Some do-it-yourselfers may be up for trying their hand at some smaller-scale core work, though; we’ll guide you through that stuff, too.

Before You Drill, Protect Yourself

Make sure you wear proper safety equipment when doing concrete work, especially when dust is involved. And there’s certainly going to be plenty of concrete dust in the air when you’re drilling. Don gloves, protective eye gear, earplugs, and a proper mask. The mask is especially critical, as concrete is likely to contain crystalline silica. Inhaling silica dust can greatly increase your risk for serious ailments, including silicosis and kidney disease. Be serious about your safety.

The Right Tools

With the right masonry bit, you can get the job done with most rotary drills, but concrete can wreck your motor. Older concrete also tends to be denser and more difficult to drill, which can be a little too much for your standard rotary drill. So, if you want a drill designed to bore into that concrete floor or wall, consider ourHusqvarna DM 220 Core Drill, an easy-to-handle, high-tech, powerhouse of a drill with a built-in leveling system and an automatic shutoff sensor that powers down when the drill is overloaded, ensuring a long life for the motor: a drill designed for the task helps you operate with efficiency and precision.

Now Get to Work

Before you drill, clearly mark where you want to drill the hole—a mistake here defeats the whole purpose. And be certain you aren’t going to be drilling into any wiring or piping. With the wall marked, it’s time to drill a pilot hole. Set the depth stop on the drill for a 1/4–inch longer than the desired hole depth. The increased depth here provides accumulation space for concrete dust buildup; again, this is absolutely a dusty process. With those steps out of the way, it’s time to start drilling in earnest.

While we’re here to tell you drilling into concrete is no great feat, you need to be ready, especially if you haven’t done it before; a harder surface does, indeed, put up greater resistance. Take on an athletic stance—feet approximately shoulder-width apart—and grip the drill like you mean it. Hold the drill firmly, but be careful to let the drill do the work; if you add extra pressure, you run the risk of breaking your drill bit. Pilot holes—also referred to as guide holes—should be drilled slowly.

The Husqvarna DM 220 Core Drill mentioned above comes with speed-reduction SmartStart technology, which comes in quite handy when drilling a guide hole. If your drill doesn’t have a speed-control option, drill in bursts.

Your pilot hole only needs to be about 1/4-inch deep. Once you’re set, do your best to blow the dust from the guide hole. A can of compressed air can come in quite handy here. You should also go ahead and vacuum up what you can.

With your pilot hole established, it’s time to complete the job and drill all the way to the depth-stop on your drill. Again, position yourself in an athletic stance and get to work. Remember not to force it. Hold firm, but let the drill do the work.

If you run up against something that seems to be stopping your drill, resist the urge to apply additional pressure with the drill; instead, remove the drill, grab a masonry nail, and tap it into the blockage with a hammer—but be careful not to embed the nail in the concrete. A few taps should clear the way for the drilling to resume.

When you’ve completed the hole, it’s again time to address the dust. Blow as much dust as you can from the hole and vacuum the accumulated dust from the area. Any little bit of relief—perhaps even borderline elation—that comes from successfully drilling into concrete may be dashed when you insert a concrete screw that won’t grip. But don’t fret. There’s a simple solution: anchors. All you need to do is find an anchor that corresponds to your concrete screw size and tap it into the hole. Before you do so, though, you should clean out as much of the remaining concrete dust as you can. With it cleared, insert the anchor and then the screw. The fit should be snug.

Heavy-Duty Jobs

The process outlined above is great for relatively small jobs—say, you are drilling into a garage or basement wall to hang shelving. But when it’s necessary to drill large-diameter holes into concrete, the process requires a little more power. Sometimes it’s necessary to bring in a professional.

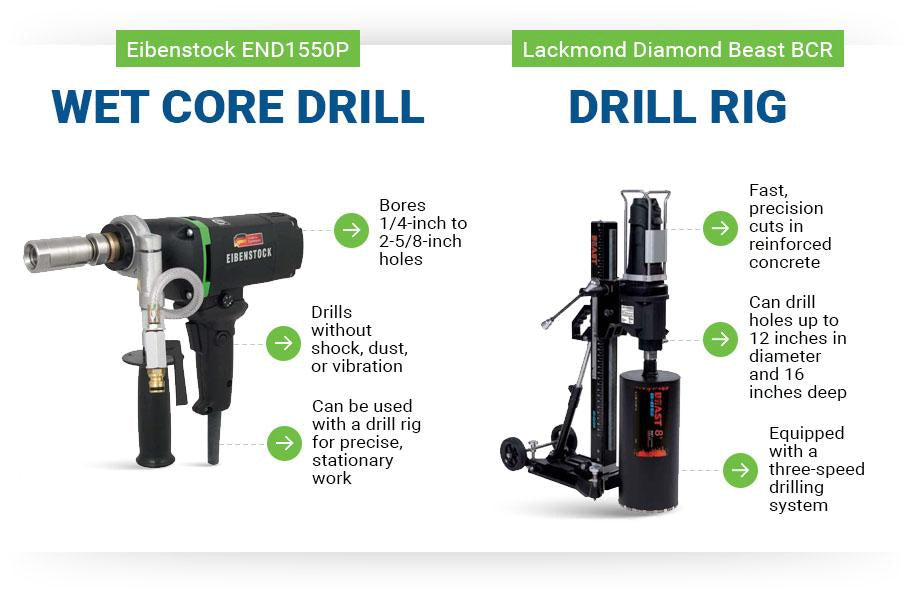

For truly large-scale jobs, it’s necessary to use a diamond core rig, such as our 2355 Lackmond Diamond Beast BCR Drill Rig. It can drill holes up to 12 inches in diameter and 16 inches deep. It also comes equipped with a three-speed drilling system. Lackmond Diamond’s BCR rigs are guaranteed to provide fast, precision cuts in reinforced concrete.

It’s best to leave the truly big stuff to a professional. But, with the right tool, the do-it-yourselfer can handle a little more than garage shelving or similarly small-scale concrete drilling. Say you want to install a signpost or stairway railing. You can get the job done with a drill such as our Eibenstock END1550P Wet Core Drill. With 13-amp power, it bores 1/4-inch to 2-5/8-inch holes into concrete and natural stone 50 percent faster than your rotary hammer. It drills without shock, dust, or vibration, and it can also be used with a drill rig for precise, stationary work.

No Biggie

There you have it. When you know what you’re doing and have the right tools, you’ll find that drilling into concrete isn’t that great a challenge after all. That is, of course, unless you need a large-diameter hole drilled out. In that case, you might want to consider hiring a pro.

Contact Contractors Direct for All Your Concrete Tool Needs

If you have questions about our concrete tools, we’re here for you! Reach out to us at 1-800-709-0002.

Image Credits:

jaboo2foto/Shutterstock.com

evkaz/Shutterstock.com